The world of welding is vast and complex, with numerous techniques, tools, and principles to master. For those new to the trade, it can be overwhelming to know where to start. However, with a solid foundation in the fundamental principles of welding, anyone can become proficient in this valuable skill. In this article, we will explore seven key welding principles as outlined by Jeffus, a renowned expert in the field.

Understanding the Basics of Welding

Before diving into the principles, it's essential to understand the basics of welding. Welding is a process that joins two metal pieces together by applying heat, pressure, or both. The goal of welding is to create a strong, durable bond between the two pieces, making them a single, cohesive unit.

Welding is used in various industries, including construction, manufacturing, and automotive. With the increasing demand for skilled welders, it's more important than ever to understand the fundamental principles of welding.

1. Safety First

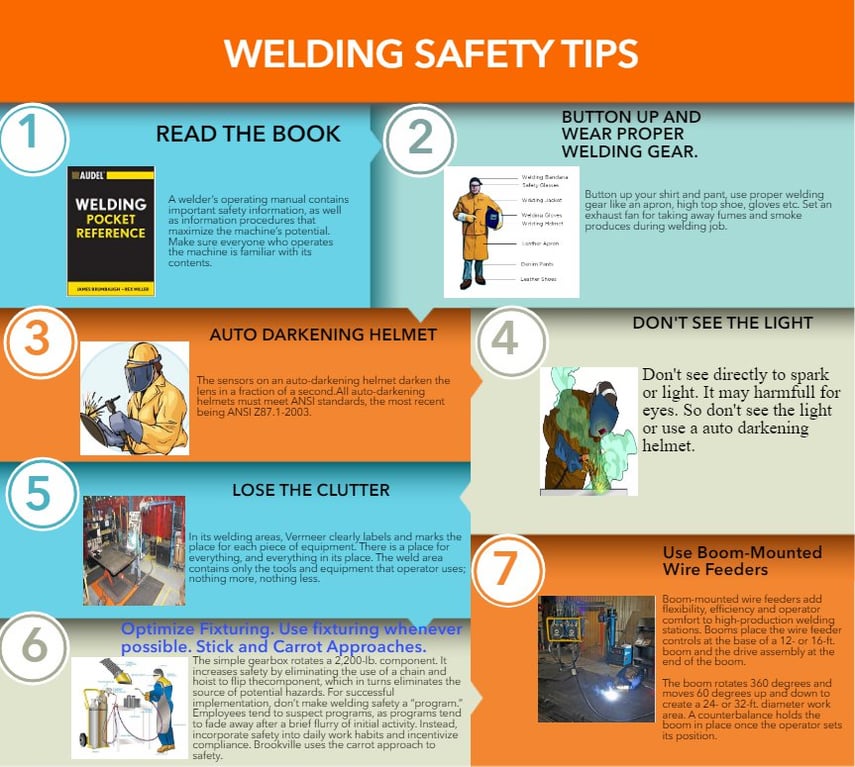

The first principle of welding is safety. Welding can be a hazardous activity, with risks of burns, eye damage, and inhalation of toxic fumes. To minimize these risks, welders must take necessary precautions, such as wearing protective gear, including gloves, safety glasses, and a helmet. Additionally, welders should ensure good ventilation in the work area and follow proper procedures for handling equipment.

2. Choosing the Right Equipment

The second principle of welding is choosing the right equipment. With so many types of welding machines and tools available, selecting the correct ones for the job is crucial. Welders must consider factors such as the type of metal being welded, the thickness of the metal, and the desired weld quality. By choosing the right equipment, welders can ensure a high-quality weld and avoid costly mistakes.

3. Preparing the Work Area

The third principle of welding is preparing the work area. A clean and organized work area is essential for producing high-quality welds. Welders must ensure the work area is free from debris, oils, and other contaminants that can affect the weld quality. Additionally, welders should use a welding table or fixture to hold the workpieces in place, ensuring accurate and consistent welds.

4. Setting Up the Welding Machine

The fourth principle of welding is setting up the welding machine. Welders must ensure the machine is properly set up and calibrated for the specific welding process being used. This includes setting the correct voltage, amperage, and wire feed speed. By setting up the machine correctly, welders can achieve optimal weld quality and minimize the risk of defects.

5. Controlling the Welding Process

The fifth principle of welding is controlling the welding process. Welders must be able to control the welding process to achieve the desired weld quality. This includes controlling the heat input, welding speed, and shielding gas flow. By controlling the welding process, welders can produce high-quality welds and minimize the risk of defects.

6. Monitoring the Weld Quality

The sixth principle of welding is monitoring the weld quality. Welders must be able to inspect the welds for defects and irregularities. This includes visual inspection, as well as using specialized tools such as weld inspection cameras and ultrasonic testing equipment. By monitoring the weld quality, welders can identify and correct defects before they become major problems.

7. Maintaining the Welding Equipment

The seventh and final principle of welding is maintaining the welding equipment. Welders must regularly maintain and inspect the welding equipment to ensure it is functioning properly. This includes cleaning and lubricating the equipment, as well as replacing worn or damaged parts. By maintaining the welding equipment, welders can extend its lifespan and ensure optimal performance.

Gallery of Welding Techniques

Frequently Asked Questions

What is the most common type of welding?

+The most common type of welding is MIG (GMAW) welding, also known as gas metal arc welding.

What is the difference between MIG and TIG welding?

+MIG welding uses a continuous wire feed, while TIG welding uses a tungsten electrode and an inert gas.

What is the importance of safety in welding?

+Safety is crucial in welding to prevent injuries from burns, eye damage, and inhalation of toxic fumes.

In conclusion, mastering the seven key welding principles outlined by Jeffus is essential for any aspiring welder. By following these principles, welders can ensure a safe and successful welding experience, producing high-quality welds that meet industry standards. Whether you're a beginner or an experienced welder, understanding these principles is crucial for achieving success in the world of welding.