Understanding Welding Principles and Applications

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. It is a crucial process in various industries, including construction, automotive, aerospace, and manufacturing. The principles of welding are essential to understand in order to apply them effectively in different situations.

The Importance of Welding Principles

Welding principles are the foundation of the welding process. They include the understanding of heat transfer, metallurgy, and the properties of materials. By grasping these principles, welders can produce high-quality welds that meet the required standards.

There are several key principles of welding, including:

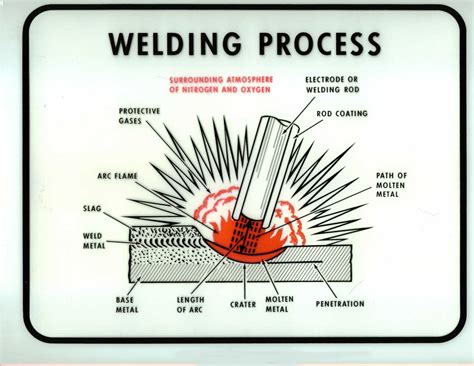

- Heat transfer: Understanding how heat is transferred from the heat source to the workpiece is crucial in welding. This knowledge helps welders to control the temperature and prevent overheating or underheating.

- Metallurgy: The study of the properties and behavior of metals is essential in welding. Welders need to understand how different metals react to heat and how they can be joined together.

- Material properties: The properties of the materials being welded, such as their strength, ductility, and thermal conductivity, are critical in determining the welding technique and parameters.

Applications of Welding Principles

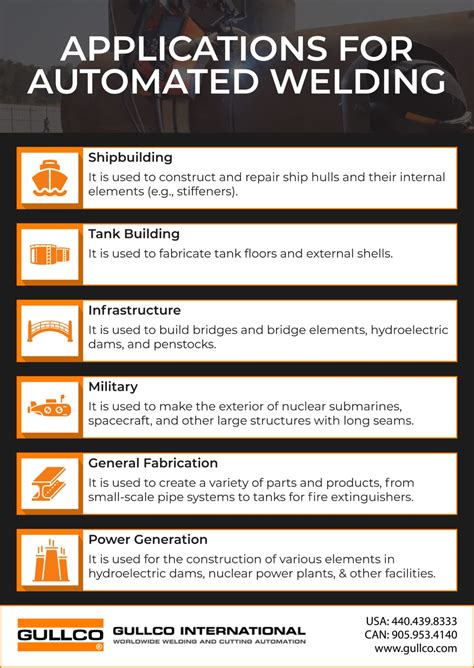

Welding principles have a wide range of applications in various industries. Some of the most common applications include:

- Construction: Welding is used in the construction industry to join steel beams, pipes, and other metal components.

- Automotive: Welding is used in the automotive industry to manufacture vehicle bodies, engines, and other components.

- Aerospace: Welding is used in the aerospace industry to manufacture aircraft and spacecraft components.

- Manufacturing: Welding is used in the manufacturing industry to produce a wide range of products, including machinery, equipment, and consumer goods.

Welding Processes

There are several welding processes, each with its own unique principles and applications. Some of the most common welding processes include:

- Shielded Metal Arc Welding (SMAW): Also known as stick welding, this process uses a consumable electrode covered in a flux to protect the arc and molten metal from the atmosphere.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, this process uses a continuous wire electrode and an inert gas to shield the arc.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, this process uses a non-consumable tungsten electrode and an inert gas to shield the arc.

- Flux Cored Arc Welding (FCAW): This process uses a special electrode that produces a flux to shield the arc.

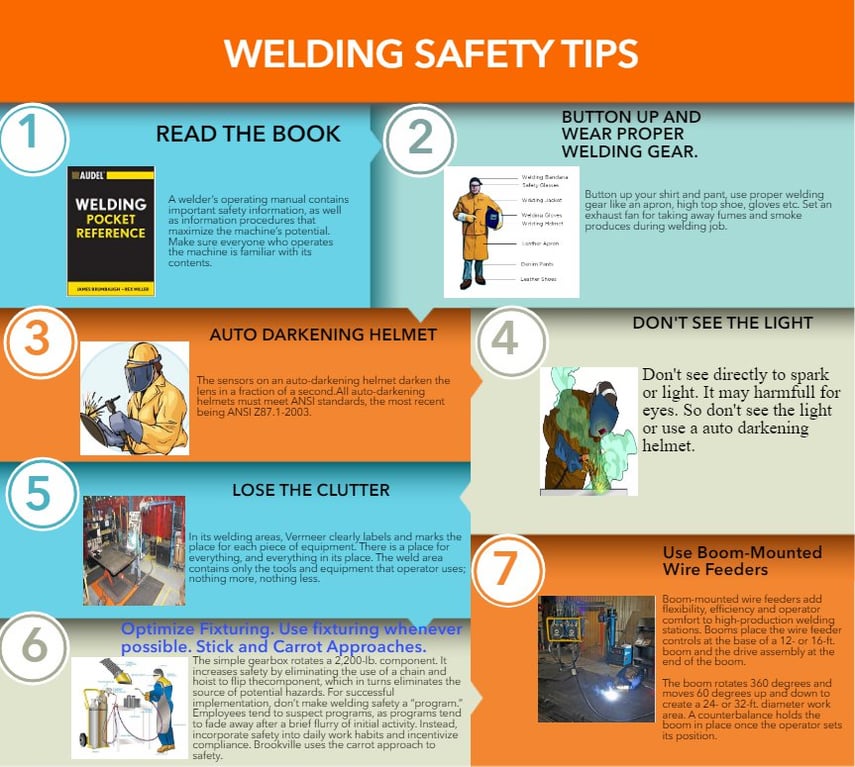

Welding Safety

Welding safety is a critical aspect of the welding process. Welders must take necessary precautions to prevent injuries and ensure a safe working environment.

Some of the most common welding safety hazards include:

- Arc flashes: These occur when the electrical arc comes into contact with the skin or eyes.

- Burns: These can occur from the heat generated by the welding process or from sparks and spatter.

- Fumes and gases: Welding can produce hazardous fumes and gases, including particulate matter, ozone, and nitrogen dioxide.

Welding Codes and Standards

Welding codes and standards are essential in ensuring the quality and safety of welds. These codes and standards provide guidelines for welding techniques, materials, and testing.

Some of the most common welding codes and standards include:

- American Society of Mechanical Engineers (ASME): This organization publishes codes and standards for welding in various industries, including power generation and petroleum.

- American Welding Society (AWS): This organization publishes codes and standards for welding in various industries, including construction and manufacturing.

- International Organization for Standardization (ISO): This organization publishes codes and standards for welding in various industries, including automotive and aerospace.

Welding Principles and Applications 9th Edition Pdf Download

For those looking to learn more about welding principles and applications, there are several resources available, including textbooks and online courses.

The "Welding Principles and Applications" textbook is a comprehensive resource that covers the fundamentals of welding, including heat transfer, metallurgy, and material properties. The 9th edition of this textbook includes updated information on welding processes, safety, and codes and standards.

Gallery of Welding Principles and Applications:

FAQs:

What are the principles of welding?

+The principles of welding include heat transfer, metallurgy, and material properties.

What are the applications of welding?

+Welding has a wide range of applications, including construction, automotive, aerospace, and manufacturing.

What are the different types of welding processes?

+Some of the most common welding processes include SMAW, GMAW, GTAW, and FCAW.