Welding is a fundamental process in various industries, including construction, manufacturing, and repair. It involves joining two metal pieces together by applying heat, pressure, or both. The process requires a great deal of skill, attention to detail, and adherence to essential principles. In this article, we will delve into the five essential principles of welding, highlighting their importance and providing practical examples.

Understanding the Basics of Welding

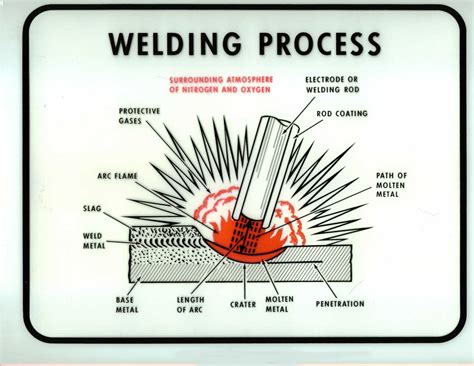

Before we dive into the principles of welding, it is crucial to understand the basics of the process. Welding involves the application of heat to melt and join two metal pieces together. The heat can be generated through various sources, including electrical arcs, flames, or lasers. The choice of welding process depends on the type of metal, its thickness, and the desired outcome.

Principle 1: Safety First

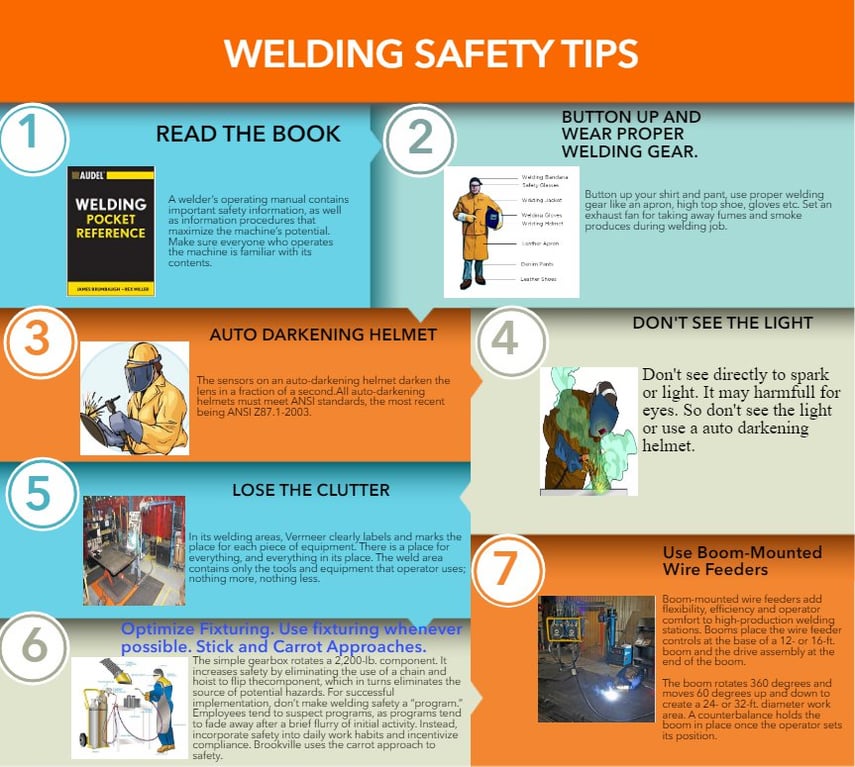

Safety is the most critical principle in welding. Welders are exposed to various hazards, including electrical shocks, burns, and injuries from sharp objects. To ensure a safe working environment, welders must adhere to strict safety protocols, including:

- Wearing personal protective equipment (PPE), such as helmets, gloves, and safety glasses

- Ensuring proper ventilation to prevent inhalation of fumes and particles

- Keeping the work area clean and clear of clutter

- Using proper lifting techniques to avoid injuries

Principle 2: Cleanliness is Key

Cleanliness is essential in welding, as it directly affects the quality of the weld. Contaminants, such as dirt, oil, and moisture, can compromise the integrity of the weld, leading to porosity, lack of fusion, or other defects. To ensure cleanliness, welders must:

- Clean the work area and equipment regularly

- Use a wire brush or other cleaning tools to remove contaminants from the metal surface

- Apply a cleaning solution to the metal surface before welding

- Ensure proper storage and handling of welding equipment and materials

Principle 3: Proper Equipment Selection

Proper equipment selection is critical in welding, as it affects the quality and efficiency of the process. Welders must choose the right equipment for the job, including:

- Selecting the correct welding process, such as shielded metal arc welding (SMAW) or gas metal arc welding (GMAW)

- Choosing the right electrode or filler metal for the job

- Ensuring proper maintenance and calibration of welding equipment

Principle 4: Control of Heat Input

Control of heat input is essential in welding, as it affects the quality and integrity of the weld. Welders must control the heat input to prevent overheating, underheating, or other defects. To achieve proper heat control, welders must:

- Monitor the welding temperature and adjust as necessary

- Use the correct welding technique, such as welding speed and angle

- Ensure proper shielding and protection of the weld area

Principle 5: Quality Control

Quality control is the final principle of welding, as it ensures that the finished product meets the required standards. Welders must inspect the weld for defects, such as porosity, lack of fusion, or cracks. To ensure quality control, welders must:

- Inspect the weld visually and using non-destructive testing (NDT) methods

- Conduct destructive testing, such as tensile or bend testing, to evaluate the weld's mechanical properties

- Document the welding process and results to ensure traceability and accountability

Gallery of Welding Techniques:

FAQ:

What is the most critical principle of welding?

+Safety is the most critical principle of welding, as it ensures the protection of the welder and others in the surrounding area.

What is the purpose of cleaning the metal surface before welding?

+Cleaning the metal surface before welding removes contaminants, such as dirt, oil, and moisture, which can compromise the integrity of the weld.

What is the importance of quality control in welding?

+Quality control ensures that the finished product meets the required standards, preventing defects and ensuring the safety and integrity of the weld.

We hope this article has provided valuable insights into the essential principles of welding. By following these principles, welders can ensure a safe, efficient, and high-quality welding process. Remember to always prioritize safety, cleanliness, proper equipment selection, control of heat input, and quality control to produce exceptional welding results.